A wide r ange of densities is availa ble starting from 10 to 40 kgm 3 whereas. As well as for roadway and runway sub-grade insulation and foundation insulation.

Geofoam Retaining Walls Insulfoam

Whether you want inspiration for planning a retaining wall renovation or are building a designer retaining wall from scratch Houzz has 21764 images from the best designers decorators and architects in the country including Maria Hickey Associates Landscapes and Envision Landscape Studio.

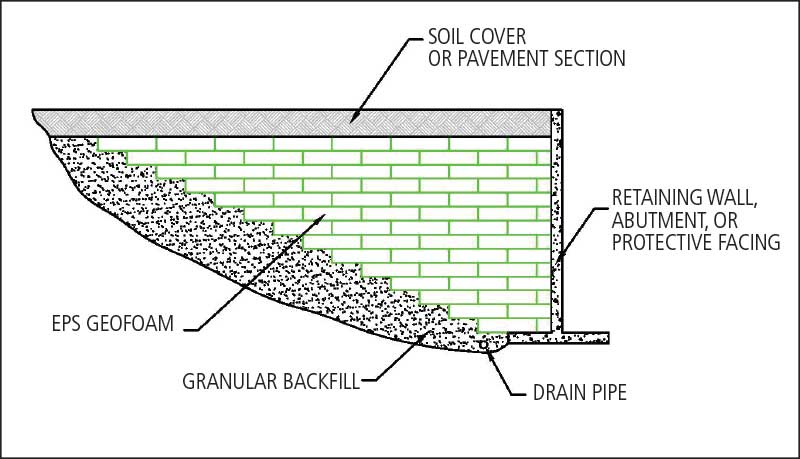

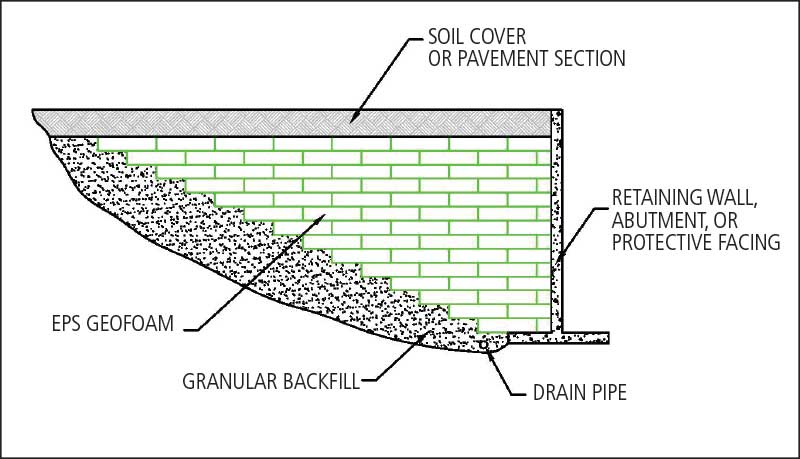

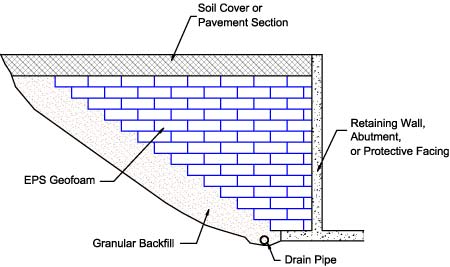

. Connect With Top-Rated Local Professionals Ready To Complete Your Project on Houzz. Expanded Polystyrene EPS geofoam is one of the most effec- tive solutions for reducing lateral earth pressure resulting from assisted backfill. Placement of geofoam behind retaining structures and below-grade walls can offer advantages of reduced lateral pressure lower settlements improved water proofing and better insulationThe central concept in using geofoam as a retaining structure backfill is to substitute as much of the soil in the active or at rest wedge with geofoam to the extent desired.

Get a Free Estimate Today. The use of EPS geofoam behind earth retaining structures such as bridge abutments can reduce lateral stresses. ABSTRACT Geofoam refers to a geosynthetic closed cell foam product used in civil engineering applications.

Browse Profiles On Houzz. EPS has been used in highway construction in Europe since the early 1970s and was first used in New York in 1996. STRENGTH EPS geofoam is available in a range of compressive resistances.

Contact Our Team Of Structural Repair Experts. Ad Find The Best Retaining Wall Construction In Your Neighborhood. Retaining Wall Ideas Designs.

As a structural fill Geofoam is designed to provide structural support in its wide variety of applications from supporting loads on retaining walls to traffic on roadways. They are used to bound soils between two different elevations often. The EPS15 geofoam was delivered in 10 precut blocks ranging form 8 x 12 x 48 to 8 x 30 x 96 to eliminate the need for any cutting on site.

EPS geofoam can be used as backfill behind retaining and buried structures to greatly reduce lateral pressures on the structure. RETAINING WALLS Geofoam is used as backfill behind retaining walls to greatly reduce lateral pressures. Along with the orientation of EPS geofoam the length of the base slab of L-.

The lower weight of geofoam allows construction workers to easily construct segmental retaining walls in a quick and efficient manner. The most acting parameter in the design of the retaining walls is the lateral earth pressure resulting from backfill mass. EPS has a density that is less than 1 of typical soil fills.

Vertical stresses beneath embankments or to reduce lateral stresses on retaining walls abutments or foundations. The concept is to place the fill in a wedge-shaped configuration with the natural or built up soil behind the retaining wall shaped at a sufficient angle of repose so that it is self-supporting. BRIDGE ABUTMENTS Geofoam is used to safely support highway loading without over-stressing the underlying soils and to reduce differential movement.

The low mass and relatively high compressibility of GeoSpec fill material offers an additional advantage by limiting horizontal forces against retaining structures. A great lightweight alternative material for constructing retaining walls is EPS geofoam. EPS Geofoam is used in geotechnical applications such as lightweight fill for construction on soft ground for slope stabilization and retaining wall or abutment backfill.

According to Wikipedia a retaining wall is defined as structures designed to restrain soil to a slope that it would not naturally keep to typically a steep near-vertical or vertical slope. Material Properties The I-15 Reconstruction Team specified geofoam with no more than five percent regrind content. Advantages of using EPS geofoams are well.

The retaining wall could then be constructed and backfilled with Geofoam materials in front of and benched into the created backslope as shown on the section drawing at station 12050. This article will explore the benefits of a Geofoam retaining wall for highway and bridge construction projects. When used properly behind a retaining wall is reduces or completely eliminates lateral pressure on the wall.

As such designers typically ensure the exact type of Geofoam used has the compressive strength needed to support design loads and stay within its elastic stress-strain range of about one percent. This was accomplished by full load compensation which meant subexcavating a volume of soil equal to the weight added by the new construction. Ad Solutions For Every Foundation Problem.

An example application is the use of geofoam behind retaining walls as an alternative to conventional soil fill material. Ad Geosynthetic Products Solutions To Enhance The Worlds Infrastructure The Environment. A project designer can choose the specific type of EPS required to support the design loading while minimizing cost.

Design Considerations g UV Degradation Geofoam should not be left uncovered more than 90 days. Geofoam density ρ is one of the controlling factors in the design of rigid retaining walls with such inclusion. We Specialize In Foundation Problems Of All Types.

UV exppg yqosure times greater than 90 days require power-washing to remove degraded geofoam surface where the load distribution slab is placed Side surface where tilt-up panel wall is placed do not require power-washing. Advantages to using EPS include. Investigations on the properties of EPS geofoam and the related design problems have also been carried out 1-24.

In fact geofoam blocks weigh 100 times less than traditional retaining wall materials. LIGHTWEIGHT ROADS Geofoam is used to replace heavy fill materials to reduce settlement. Because the horizontal pressure acting on a retaining wall is proportional to the weight of the backfill a less robust retaining structure is needed if the backfill soil in the active zone behind the retaining wall is replaced with EPS geofoam.

We estimate that the retaining wall could be constructed with a concrete fascia panel wall and footing for this. Geofoam embankments were designed to produce zero net load on the foundation soils. The geofoam blocks were stacked behind the wall with some earth placed behind the.

The heaviest block weighed just 12 pounds. Of EPS geofoam behind the L-shaped retaining wall to control the deflection under the seismic forces. The EPS material itself has a high compressive resistance making it ideal.

Eps Geofoam Inclusion Behind A Retaining Wall Download Scientific Diagram

Eps Geofoam Inclusion Behind A Retaining Wall Download Scientific Diagram

Geofoam Retaining Wall Fill Geofoam International

Typical Retaining Construction Canada

Geofoam Retaining Wall As Soil Substitute Popular Choice For Engineers

Retaining Structures Geofoam America

Sustainability Free Full Text Evaluating The Role Of Geofoam Properties In Reducing Lateral Loads On Retaining Walls A Numerical Study Html

0 comments

Post a Comment